NASA Michoud Assembly Facility

NASA’s Michoud Assembly Facility in New Orleans is one of the largest manufacturing sites in the world.

The Historic New Orleans Collection

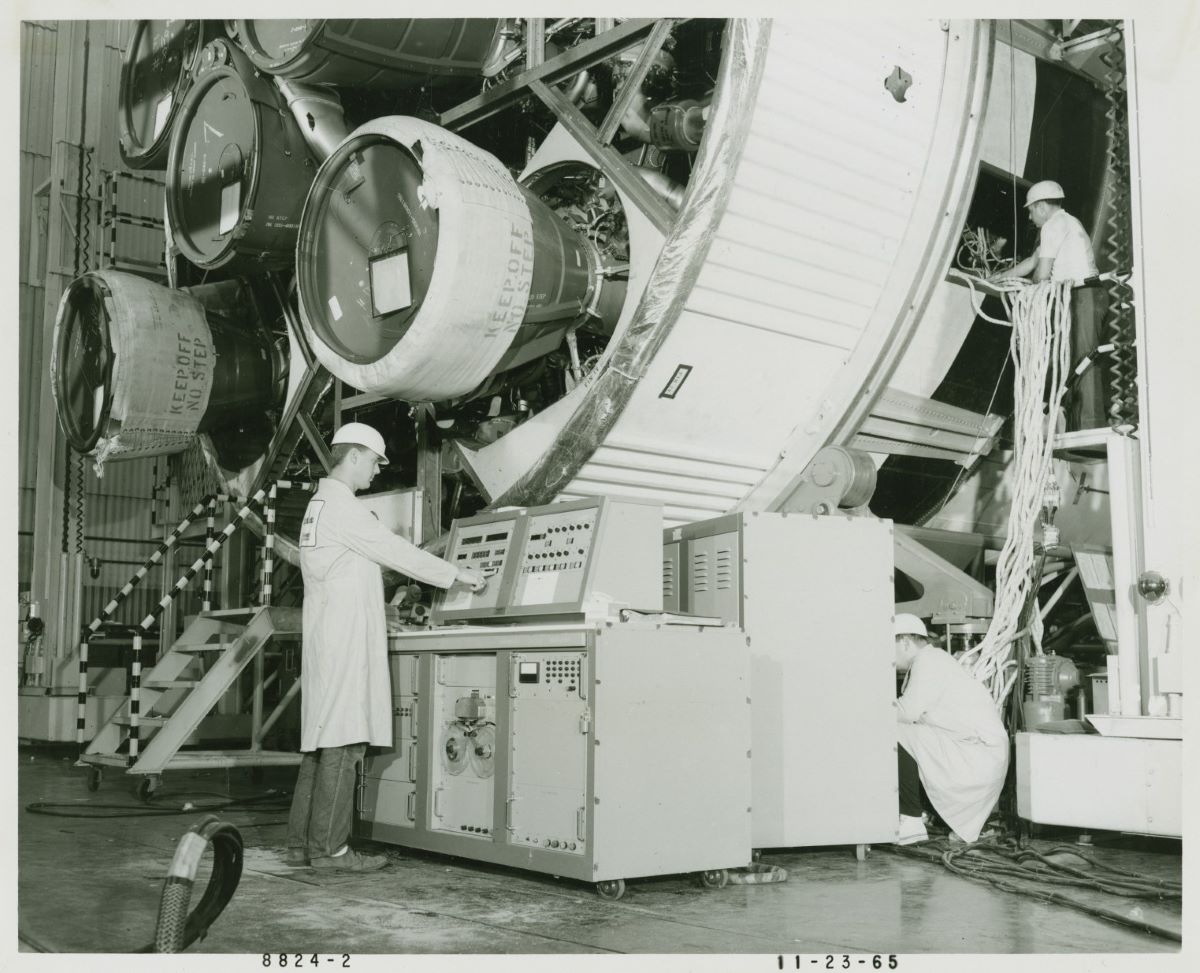

SIB-5 Continuity and Megger Checks, Michoud Assembly Facility

Owned by the US government and operated by NASA, the Michoud Assembly Facility in New Orleans East is one of the largest manufacturing sites in the world. Since 1961 Michoud has primarily built large rockets and related space vehicles and components for human-crewed space missions, including for the Apollo and Space Shuttle programs. Often referred to by NASA and the press as “America’s rocket factory,” the facility’s multiple buildings sprawl across an 832-acre campus, the largest structure being the 1.87 million-square-foot main manufacturing building.

Since 2011 Michoud’s NASA work has mostly revolved around manufacturing the main rockets and related components for the agency’s Space Launch System (SLS), which, as part of the Artemis program, is scheduled to carry human crews to the moon and beyond starting as early as 2025. Michoud also houses several other government, commercial, and civil tenants. About thirty-five hundred people are employed across all of Michoud.

History

The land on which the Michoud Assembly Facility now sits was originally part of a larger parcel of land granted in the 1700s by Louis XV of France to a New Orleans merchant, Gilbert Antoine de St. Maxent. Frenchman Antoine Michoud purchased some of the land in 1827, building and operating a sugarcane plantation and refinery on what would become the NASA site. Michoud’s heirs operated the refinery into the early twentieth century, and two of its smokestacks remain preserved on the site today.

In 1940 the US government purchased one thousand acres of the former refinery land in what was then called the village of Michoud to house a $30 million shipyard operated by Higgins Industries to build ships for World War II. The government dredged a canal to connect the site to the Intracoastal Canal, and Higgins built the main manufacturing building that stands today. However, a lack of steel led to the shipbuilding program’s cancellation, and Higgins instead built plywood cargo planes and then aluminum planes. In 1951 the Chrysler Corporation built tank engines at the facility for the Korean War and installed a fifty-five-hundred-foot paved runway. The runway has since been decommissioned.

NASA acquired the Michoud facility in 1961 and placed it under the management of NASA’s Marshall Space Flight Center in Huntsville, Alabama, which remains the case today. The facility began building the first, largest stages of the Chrysler- and Boeing Corporation-built Saturn rockets that would power the Apollo missions and continued to do so through the end of the Apollo program in 1972. For the next thirty-eight years, the fifteen-story-tall external fuel tanks for the Space Shuttle were built at Michoud by Martin Marietta Corporation. The last of the 136 fuel tanks manufactured there was flown in 2011.

Michoud had been scheduled to transition from its Space Shuttle work to manufacturing components of NASA’s planned Constellation program, missions intended to send astronauts to the moon and Mars. However, Constellation was canceled by the government in 2010. In 2011 NASA instead committed to the Artemis program for the moon and other missions, including the SLS rocket. Michoud was tapped to build the SLS core rocket stage, which was, at the time, the largest and most powerful rocket stage ever built, as well as other major components of the SLS. Boeing is the prime contractor for the SLS core stage.

Assembly Facility

Most work on space vehicles at Michoud occurs in the facility’s main manufacturing building and the two attached “vertical assembly” buildings. (Contrary to many popular accounts, NASA did not rename this facility the “Chris A. Hadfield Rocket Factory” in 2012 to honor the accomplished Canadian astronaut.)

The main building, which has a footprint of 1,680 ft. by 1,115 ft., is where most component fabrication, welding, and assembly are performed. However, the forty-foot height of the main building’s interior working space is too low to accommodate the welding of the separate cylinders that are stacked to make up the outer body of an entire SLS rocket core stage. That welding occurs in one of the two attached vertical assembly buildings, which are 170 feet tall. One of the vertical assembly buildings contains what NASA claims is the world’s largest spacecraft welding tool, a robotic “stir-welding” tank that can accommodate multiple core-stage components. When finished the SLS core stage is 200 feet tall. Smaller buildings nearby house the fabrication of smaller components.

Completed rocket stages can be moved from the assembly buildings on transport vehicles over on-site roads to either highway for ground transportation or to a nearby on-site pier on the Intracoastal Waterway, where a barge can take the rocket stage to the Mississippi River or the Gulf of Mexico. Finished stages are shipped to either the Kennedy Space Center in Florida or the Marshall Space Flight Center in Alabama.

SLS and Artemis

The SLS rockets are designed to carry the Orion crew module to the moon and beyond, in missions that make up NASA’s Artemis program. The first Artemis mission, a successful uncrewed voyage to moon orbit and back, took place in 2022, between November 16 and December 11. Artemis 2 is tentatively scheduled for 2025 and will send a four-person crew more than five thousand miles past the moon before returning. The government estimates the Artemis program to cost $93 billion through 2025.

Later in the decade, NASA plans an Artemis 3 mission to land a crew on the moon and an Artemis 4 mission to send a crew to a space station orbiting the moon. The station will be constructed starting in 2025 by an international partnership. All Artemis missions will rely on the core SLS stage built at Michoud, which is currently constructing the core stages for Artemis 2 and 3. As of 2024 Michoud has also begun work on the Exploration Upper Stage, a second-stage SLS rocket planned for use in the Artemis 4 mission and beyond.

Michoud Tenants

US government tenants at other buildings on the Michoud campus include the Coast Guard and the Department of Agriculture. There are also several commercial tenants, including General Electric and Textron. A previous tenant through 2016 was film studio Big Easy Studios, which filmed scenes from several major Hollywood films at Michoud, including Ender’s Game (2013) and G. I. Joe: Retaliation (2013).

In 2023 plans were begun for the commercial development of a $100 million fifty-acre industrial and office park on the campus, intended to provide more than 1 million square feet of manufacturing and office space and expected to be completed over several years. That will still leave Michoud with about 170 acres of green fields that could be developed in the future. In 1988 a Boeing 737-300 lost power and made an emergency landing on those fields without injuries. It took off from Michoud’s former runway two weeks later, without passengers.

Community Impact

NASA estimates that its economic impact on Louisiana, primarily through its Michoud activities, includes 2,601 jobs that provide workers with $150.1 million in income, $493.6 million in economic output, and $16.2 million in tax revenues for the state and local governments.

Michoud also houses the National Center for Advanced Manufacturing, which develops and shares new aerospace manufacturing technologies with the commercial sector. Center partners include NASA, the University of New Orleans, Louisiana State University, and the state of Louisiana. Michoud also hosted the launch of the Greater New Orleans Regional Advanced Manufacturing Partnership, a workforce development partnership between the US government, the commercial sector, philanthropic groups, and education and training organizations.

NASA provides group tours of Michoud by appointment to schools and organizations. The facility also engages in STEM-oriented educational and vocational partnerships with local colleges and universities, including Nunez Community College. In addition, Michoud partners with the nonprofit economic development group Greater New Orleans, Inc. to host female high-school summer STEM interns.

Weather-Related Events

Michoud was partially protected in 2005 from Hurricane Katrina and its associated flooding by surrounding ridges, but the roof of the main building was damaged, letting in water. Thirty-eight NASA Michoud employees stayed on site through the worst of the resulting flooding to keep the building’s pumps operating, enabling the pumps to remove more than 1 billion gallons of water, minimizing interior damage. The feat earned each of them NASA’s Exceptional Bravery Medal.

In 2017 the main building and one other building were damaged by an EF3 tornado, injuring five people. The incident was one factor in the Artemis 1 launch being postponed from 2021 to 2022.