Magazine

Shrimp Ambassadors

Over 10 million pounds of shrimp pass through their processing facilities each year, making Big Easy one of the leading shrimp processors in Louisiana

Published: September 1, 2016

Last Updated: May 2, 2019

Larry Avery at Big Easy’s plant in Lake Charles. Photo by Tyler Walker

A world away in Sulphur, Louisiana, Abraham owned a little place called the Boudin Kitchen, which specialized in sausage and its namesake, and he was hell-bent on getting Avery to join him. Despite his aversions, Avery was no stranger to the corporate world. His first venture was Aquatech Engineering & Supply, which had 12 locations across the country, and was by all measures a success. He sold the enterprise to a Chicago-based corporation and stayed on for two years to complete the transition.

After Chicago, Avery’s plans included coming back to Lake Charles and starting a small and manageable mini-storage business to ease him into retirement — his plans didn’t include getting knee-deep into the seafood industry.

“I came from a fairly large company with managing officers all around the country and went to a self-storage business with one employee,” said Avery as he sat in his office at Big Easy Foods, surrounded by family photos and memoirs of his successful enterprises. “So, as you can imagine, after three months I got a little bored.”

Retirement just wasn’t ready for Avery, and he finally agreed to Abraham’s relentless business pitches. But instead of joining him at the Boudin Kitchen, Avery threw a curveball and suggested beginning an entirely new food industry venture.

Shrimp boats in Dulac, La.

Louisiana seafood has an annual economic impact of $2.4 billion on the state, and one out of every 70 jobs in the state is tied to its industry. Southwest Louisiana has an incredibly deep affection for seafood and the culture surrounding it. Avery and Abraham wanted to take a swim in that world.

Big Easy Food began 15 years ago as French Market Foods and focused on producing and selling sausage and boudin in stores across Southwest Louisiana. The brand became synonymous with high quality products with a distinct and beloved Louisiana flare. Soon they were adding a few other items to the menu.

Cameron Parish is perched on the Gulf, directly south of Lake Charles in Calcasieu Parish. Despite the hurricanes, the oil spills and the constant threat of some other future disaster, the coastline of Southwest Louisiana still thrives with a diverse and delicious ecosystem of blue crabs, crawfish, alligator, oyster beds and, of course, shrimp.

Inside the Big Easy Foods plant on the city’s main drag on Ryan Street, Avery introduced each member of his staff with a footnote about their role in the company, such as “The company would collapse without her” or “He’s the guy to talk to about boudin.”

Over 10 million pounds of shrimp pass through their processing facilities each year, making Big Easy one of the leading shrimp processors in Louisiana.

Shrimp was the topic of the day. Besides crawfish, shrimp is perhaps the quintessential Louisiana treat that is simultaneously a major economic player in the state and the source of fond memories of mothers and fathers teaching children the best way to get the most meat when peeling the little crustaceans.

Now, 15 years after they started, Big Easy Foods knows shrimp. Over 10 million pounds of these sea insects pass through their processing facilities each year and find their way onto grills and atop salads across the nation, making Big Easy one of the leading shrimp processors in Louisiana.

“We began acquiring companies and kept evolving our brand,” said Avery. “We purchased at least 14 to 15 companies, everything from small businesses to $10 million powerhouses. We put them together, and they make up what is now Big Easy Foods.”

Avery is now fully back in the fray alongside members of his family who help to manage several prominent businesses in Lake Charles, including Crave, a specialty food store, and Crying Eagle Brewery, a highly anticipated new enterprise.

As their production peaked, Avery and Abraham put the shovel in the dirt in the middle of Lake Charles and opened a 35,000 square foot USDA plant facility to handle the ever-increasing demand for their tur-duc-hens, frozen meals, boudin, sausage and — their highest grossing product — wild caught domestic Gulf Coast shrimp.

Big Easy Foods — also known by by its legal name, Gulf Island Shrimp — is a steadfast steward in ensuring domestic shrimp, and not farm-raised overseas knock-offs, make its way to your kitchen. According to the Louisiana Seafood Marketing Board — on which Avery serves as a board member — most shrimp is farmed overseas. India, Thailand and Indonesia are the giants in shrimp production globally, and 94 percent of the shrimp we consume in America comes from farms in these countries. Much of this production has little regulatory oversight and heath codes are often pushed to the side. As a result, your next shrimp étouffée may contain traces of formaldehyde or antibiotics. Big Easy offers a healthy, locally harvested alternative.

“The quality of the shrimp coming from Big Easy Foods is unmatched,” said Avery. “The average customer today wants to know everything about what they feed their family, and they demand quality, which we eagerly supply.”

David Graham is the general manager of Big Easy Foods’ shrimp side and oversees the operations of the company’s two shrimp processing plants, which sit on either side of Bayou Plat in Dulac. His career is steeped in his father’s life as a renowned shrimper, and Graham carries this legacy with him daily.

“I’ve been in the seafood industry my entire life,” said Graham. “My father, Charles, was an icon in the domestic shrimp industry back in the 1960s and 1970s. As a kid, I did the same thing for his operations as I do at Big Easy Foods.”

Upon graduating from the University of Alabama with a bachelor’s degree in industrial engineering, Graham worked for his father’s company, which was much larger and more diverse than Gulf Island Shrimp.

“We lived in Bayou La Batre, Alabama, and my father worked as an engineer for a while until he bought his own shrimp boat,” said Graham. “Eventually he had an entire fleet of shrimp boats, and he began unloading and processing all of his own catches.”

That was back in the 1950s, and by the time the ‘60s came around, Charles Graham had developed a fully integrated shrimp processing plant and was selling all types of processed shrimp products to the food service industry. Graham grew up right in the middle of it.

Between facilities in Bayou La Batre and Pascagoula, Mississippi, Graham’s father went from a lone shrimper in the Gulf to the head of a major seafood company. When the company dissolved decades later, Graham joined Big Easy Foods as their go-to shrimp guy.

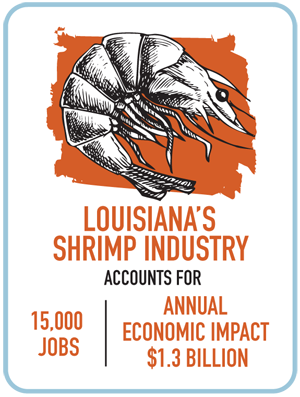

The two shrimp facilities are seated in the heart of Louisiana’s $1.3 billion shrimp industry.

“Louisiana is at the center of the best shrimping waters on the Gulf Coast,” said Graham, “and Terrebone Parish is at the center of Louisiana’s shrimp industry, and our two plants are at the center of that, so we are right in the middle of the most productive shrimping areas in the country.”

A significant amount of Big Easy Foods’ shrimp is caught within 50 miles of their Dulac plants. “I’d bet that some of it is even caught 100 feet away, right in the bayou,” said Graham.

Nearly 25,000 pounds of raw, peeled shrimp meat makes its way out of the doors each day. Before they make their way to various retail distribution channels, the shrimp are unloaded straight from the boats onto the facility docks. Despite fueling a massive demand for shrimp inside and outside of Louisiana, Big Easy Foods remains hands-on.

“We build strong relationships with the shrimpers, and we buy directly from them,” said Graham. “Some of them unload shrimp at our plants a few times a week. You get to know them, and they get to know you. We want to make sure that we’re paying them the most we can for their shrimp, and, of course, we demand that they bring in only the highest quality shrimp.”

The shrimp first head to the peeling plant, ScottCo., before heading to the value-adding plant, SeaTang. Both companies were purchased by Big Easy Foods in order to greatly expand the business and to have a full range of processing capabilities. Together, the plants have over 40,000 square feet of innovation and efficiency.

Most everything can be done at one or both of the plants. Once the shrimp are peeled at ScottCo., on one side of Bayou Plat, the shrimp are either immediately frozen in five-pound blocks to ensure the best freshness possible, or they make their way across the bayou to SeaTang where the workers will “IQF bag it” — also known as “individually quick-frozen bags.”

“Most of our shrimp goes out of Louisiana,” said Graham. “We ship it all over the country. No matter what state you’re in, if you have a bag of domestic peeled shrimp, there’s a good chance it came from Louisiana.”

Texas leads the demand for Gulf Coast shrimp, and with consumers leaning toward healthy, high protein options for dinner, shrimp sits at the top of the list. Big Easy Foods’ shrimp are sent to grocery stores in all 50 states, and even if the bag doesn’t say Big Easy Foods, it’s still likely that the shrimp came from Terrebone waters.

Today, the company employs roughly 170 people, some of which we saw in action at the plant’s meat processing facility, sorting boudin, wrapping shrimp jalapeno poppers with bacon or vacuum sealing bowls of ready-made shrimp gumbo.

There’s a monotony to the workday, yet one constant throughout any conversation with Avery and Graham was that neither man could talk about Big Easy Foods without referencing the expertise and experience of their teams.

“We have an extremely knowledgeable team,” Avery said. “We have intensive training programs, and we have the highest certification in the industry required by big chains. We have an amazing group of people. Our business is only successful because it’s backed by people who know the industry.”

—

Photos by Cheryl Gerber and Tyler Walker