World War II Industrialization in Louisiana

The United States’ entry into World War II spurred Louisiana’s recovery from the economic doldrums of the Great Depression.

Naval History and Heritage Command

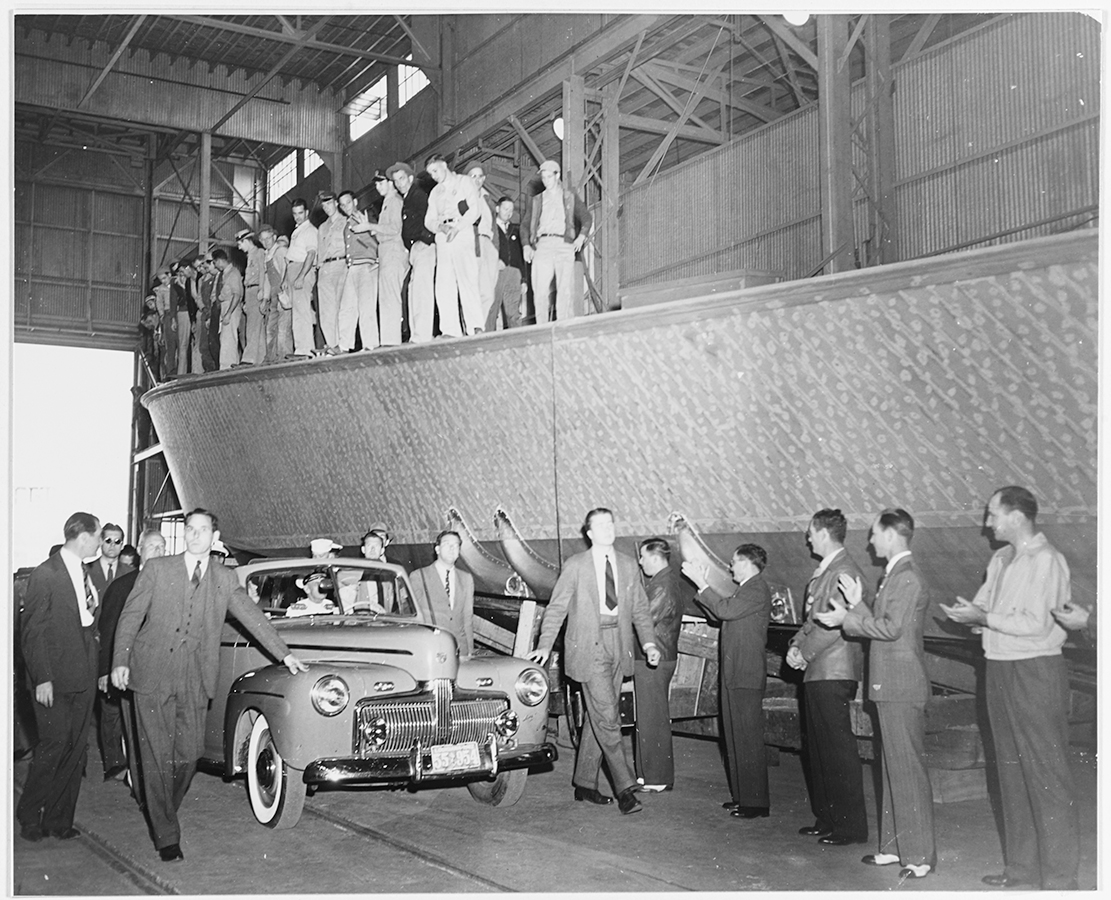

President Franklin D. Roosevelt touring Higgins Industries, 1942.

Louisiana businesses began recovering slowly from the economic catastrophe of the Great Depression before World War II started, but the United States’ entry into the war spurred unprecedented industrialization in the state and helped the economy recover completely from the collapse experienced during the 1930s. All regions of the state enjoyed some degree of economic recovery, but the major urban centers of New Orleans, Baton Rouge, and Shreveport experienced the greatest industrialization.

New Orleans

Before the war New Orleans was already more industrialized than other areas of the state, and businesses in the city produced equipment and supplies for the war effort. Louisiana Shipyards, Delta Shipbuilding Company, and Higgins Industries built Liberty Ships. Consolidated Vultee Aircraft Corporation of Downey, California, operated an aircraft production plant in the city and originally planned to build the Consolidated Model 31 “flying boat” ordered by the navy. A shortage of engines for the craft, which were also used for the more important B-29 Superfortress bomber, led to cancellation of the Model 31. The New Orleans factory then built another design of flying boat, a type of seaplane.

Smaller companies in New Orleans also produced military equipment. Rheem Manufacturing Company made shell casings, and Neptune Boat and Davit Company built lifeboats. Edwin H. Blum manufactured military uniform trousers; Federal Fiber Mills produced manila and sisal rope. Snider Poster Process Company quickened aircraft construction by producing decals that eliminated time-consuming hand-lettering of instrument panels. National Blow Pipe and Manufacturing Company constructed containers for shipping ammunition, and Crescent Bed Company built berths for Liberty Ships. International Lubricant Corporation produced special greases ordered by the armed forces to keep equipment running in extremely cold, hot, or wet conditions. Other plants produced other goods.

Andrew Jackson Higgins’s shipbuilding facilities, Higgins Industries, were the largest war industries in New Orleans and the state. Higgins built its first boats for the military in 1936 when the army ordered two river-steamer inspection boats. The company’s specialty was landing craft that could rush onto a beach without damage. The navy ordered its first landing boats from the company in 1938, and Higgins Industries produced them for the United States, Britain, Finland, and Holland during World War II. “Higgins Boats” were built in several configurations, depending on specialized need, and the company also built ramp-type welded-steel tank lighters, and patrol-torpedo (“PT”) boats by 1941.

Higgins Industries sold more than 14,000 combat boats of all types to the Allies, and the United States Navy reported in 1943 that he and his company had designed or built the majority of its 14,072 vessels. Higgins’s contributions to victory were so important that General Dwight Eisenhower, who served as Supreme Allied Commander of the Allied Expeditionary Force, supposedly referred to him as “the man who won the war for us.”

Higgins had trouble obtaining contracts for the cargo ships known as Liberty Ships and airplanes at his huge new Michaud plant in New Orleans, but used the facility to manufacture rescue boats and some mechanical parts for the first atomic bombs.

Baton Rouge

As home of the massive Standard Oil Company of Louisiana refinery, pre-war Baton Rouge was a major oil refining center. Because of this refinery and other major industries, the city became a vital part of American war production.

The Standard Oil complex included the first catalytic cracking plant ever built, and it enabled the plant to produce aviation fuel and create by-products needed to make synthetic rubber. The complex also made high-octane blending agents for aviation fuel, synthesized both ethyl and isopropyl alcohol from petroleum, and produced synthetic rubber. The refinery produced its one billionth gallon of aviation fuel by June 1945, and the government estimated that it fueled one in every fifteen planes used in the war.

Baton Rouge was also a concentration depot for United States Army supplies. This project more than doubled the railroad tracks in the Illinois Central Railroad yards, thus improving its transportation capacity. In addition, the Aluminum Company of America plant located in Baton Rouge manufactured enough aluminum to produce two thousand fighter planes per month by April 1944.

Shreveport

Shreveport was the center of wartime prosperity in northwest Louisiana. J. B. Beaird Company produced shell casing, tanks to produce synthetic rubber and store high-octane gasoline, landing barge anchors, and armored tank parts. Brewster Company transformed raw steel tubing into bomb bodies and shipped them to shell-loading plants.

The Shreveport Chamber of Commerce successfully lobbied the army ordnance department for a munitions plant in northwest Louisiana. The War Department announced in April 1941 that it intended to locate an ordnance plant at Minden in Webster Parish rather than more urbanized Caddo Parish. These facilities had to be located in relatively unpopulated areas because of the possibility of explosions. Construction costs for the Minden Shell Loading Plant exceeded estimates because the site was too flat to drain properly without an extensive network of ditches and canals. Nevertheless, the massive plant encompassed 16,025 acres by 1943 and became a vital component in American war production.

Lake Charles

Lake Charles was partially industrialized before the war when Mathieson Alkali Works and Swift Packing Company built facilities in the city. World War II brought additional development when Mathieson enlarged the alkali plant, Cities Service Company built a high-octane gasoline refinery, and Firestone Rubber Company built a plant to produce synthetic rubber. Defense Plant Corporation financed construction of plants to produce butadiene, ammonia, and magnesium in Lake Charles, and in addition Calcasieu Parish produced about twelve million barrels of oil annually while about twenty-five million barrels moved through the port in Lake Charles each year.

Other Regions

Other regions of Louisiana prospered while contributing to the war effort in other ways. Central and western Louisiana trained thousands of troops in training camps and hosted the series of Louisiana Maneuvers that contributed to the local economy. Monroe trained aviation navigators. These regions benefited economically while accommodating thousands of soldiers.